Shape memory alloys for industrial applications

TSS InnovationsProjekte GmbH designs, manufactures prototypes and produces devices and elastic elements in shape memory alloys (mainly NiTi). Shape memory alloys represent a class of innovative materials that can completely recover large deformations (up to 8%) by heating (Shape Effect) or by removing the load (superelasticity). TSS InnovationsProjekte GmbH, based on the knowledge of the functional properties of shape memory alloys, has gained a significant experience in the cold working and optimization of the final properties of the devices, providing solutions adapt to the customers' products.

The company's production process offers high quality standards on large-scale productions employing traditional materials. This capability has been perfectly integrated into the production processes of shape elements, ensuring reproducibility and reliability of functional properties. Elastic elements made of shape memory alloys are widely used in industry, particularly as actuators for the production of flow controllers in the air conditioning (VAC), Thermo Hydraulics and Automotive fields, as security elements in the Fire Protection sector, and also for many biomedical applications.

Flexibility is our own DNA

SHAPE MEMORY EFFECT:

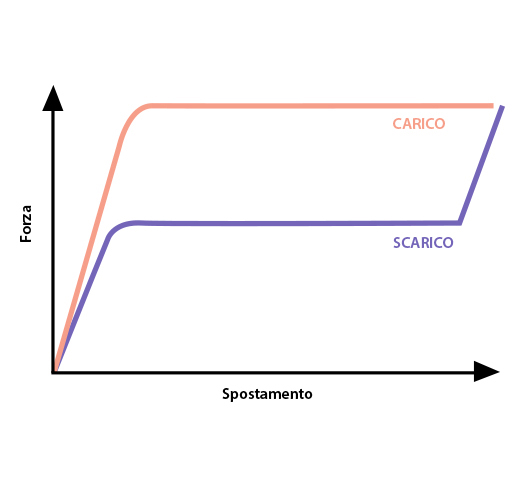

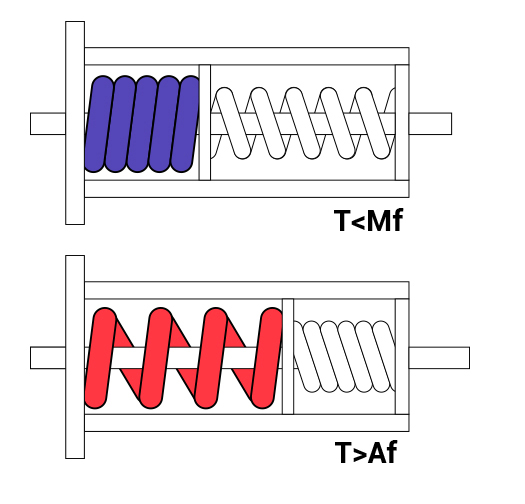

The shape memory material is subject to a crystalline structure transformation, between a deformable phase stable at low temperature and a rigid phase stable at high temperature stable. The deformations accumulated at low temperatures can be recovered by heating. Depending on the type of constraints applied during recovery, there are different behavior: • Free Recovery: shape recovery takes place in a free manner, without constraints: the shape is completely recovered, no force is generated. • Constraint recovery: when a fixed constraint impedes the shape recovery over a certain limit. In this case the material generates a lot of force once the constraint is met. • Actuators: In case the constraints yields, the stress applied by the material is coupled with a shape recovery up to a point of equilibrium. An example of this is shown schematically in the figure, where a shape memory spring works against a normal steel spring. At low temperature the shape memory material has a low rigidity so that the steel spring can keep it compressed; when temperature rises over a transformation point, the shape memory spring compresses the antagonist steel spring thereby achieving a displacement of the slider. Once the spring has cooled down, it returns to the initial configuration ready to repeat this actuation.